The Stalker Pumps ISO Hydraulic Driven Series includes the ISO 4600, 4700, 6300, 6400 and 7000 ranges. The Stalker Pumps ISO Hydraulic Driven Series are manufactured in Western Australia to the highest quality standards, employing the best engineering practices available.

Specifically designed for mobile dust suppression, the main advantage of the ISO Hydraulic Driven Series is that it eliminates the need to carry couplings in stock or have a specialist on hand to align them. The speed of dismounting and remounting the unit onto the water cart itself significantly reduces the time taken to service the pump, while at the same time, reducing the costs associated with scheduled servicing.

Features:

- No coupling drive, eliminating the need to carry couplings in stock or have a specialist on hand to align them.

- 2 Bolt SAE Flange Mounted easy on/off Hydraulic Motor.

- Smaller footprint – approximately 200mm smaller in length than standard ISO configurations.

- Casing – Standard cast iron AS1830 T260 grade. Alternative options:

– Austenitic iron AS1833 203

– Stainless steel AS2074/H6B

– Ceramic coating - Mounting feet are incorporated into the casing casting.

- Flanges – Dimensions are to AS2129 table E as standard, optional ANSI and DIN flanges available on request.

- Impeller – Standard cast iron AS1830 T260 grade. Alternative material options, 316 stainless steel and zinc-free bronze, also available.

- Mechanical Seals: Standard Carbon/Ceramic/Nitrile. Further options available on request.

- Bearings – Heavy duty deep groove ball bearings. Greasable and fitted with grease nipples. Available as sealed for life, or running in oil filled housing. Bearing housing is fitted with breather, oil level and drain plugs. Optional constant level oilers and oil cooling also available.

- Bearing Pedestal – Hydraulic close-coupled pedestal is a version of the Stalker standard ISO bearing pedestal, which provides interchangeability of bearings and lip seals between standard ISO and the Hydraulic version.

- Spline Shaft Drive Arrangement – enables even distribution of shaft loading and power transfer, eliminating axial load transfer to motor shaft, elongating motor life.

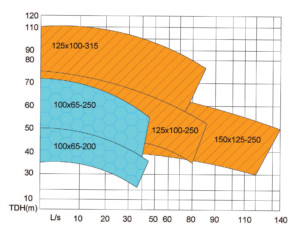

Curves

Tech Specs

|

Pump Model Number |

Hydraulic Drive Model Number | Suction Size | Discharge Size | Impeller Type | Flow Range | Head Range |

Max Operating Speed (RPM) |

| 100 x 65 – 200 | GM 130A | 100 NB | 65 NB | Closed | 15-33L/s | 26-33m | 2000 |

| 100 x 65 – 200 | GM 230A | 100 NB | 65 NB | Closed | 18-40L/s | 36-48m | 2400 |

| 100 x 65 – 250 | GM 130A | 100 NB | 65 NB | Closed | 18-33L/s | 42-50m | 2000 |

| 100 x 65 – 250 | GM 230A | 100 NB | 65 NB | Closed | 20-41L/s | 60-72m | 2400 |

| 125 x 100 – 250 | GM 175C | 125 NB | 100 NB | Closed | 37-78L/s | 36-50m | 2000 |

| 125 x 100 – 250 | GM 230A | 125 NB | 100 NB | Closed | 43-90L/s | 52-72m | 2400 |

| 125 x 100 – 315 | GM 176C | 125 NB | 100 NB | Closed | 37-62L/s | 62-73m | 2000 |

| 125 x 100 – 315 | GM 265A | 125 NB | 100 NB | Closed | 37-62L/s | 62-74m | 2400 |

| 150 x 125 – 250 | GM 176C | 150 NB | 125 NB | Closed | 43-115L/s | 34-50m | 2000 |

| 150 x 125 – 250 | GM 265A | 150 NB | 125 NB | Closed | 47-135L/s | 50-70m | 2400 |